Right trading

SECTORS AND PRODUCTS

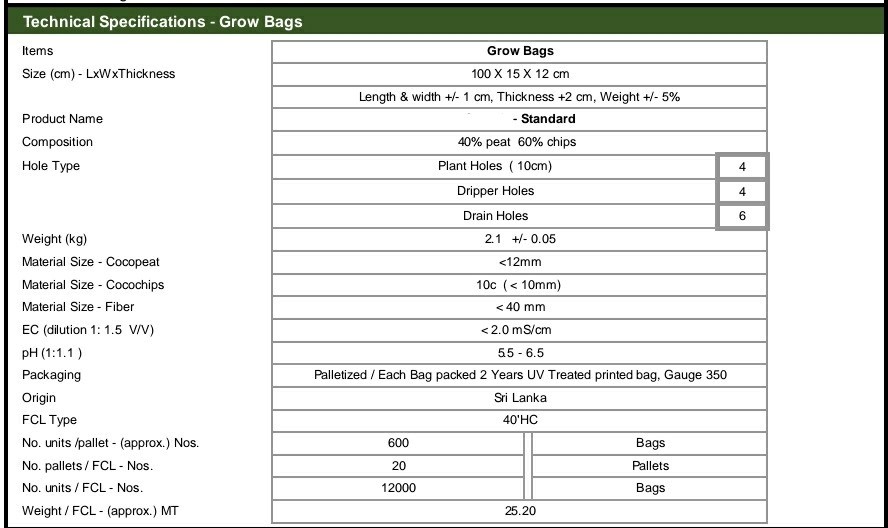

COCO PEAT

Coco Peat is a product obtained from the outer fiber of the coconut shell. It can hold about 10 times its volume of water. It reduces the frequency of irrigation. It is not compact like normal soil, it helps the roots to aerate and breathe, the roots and the plants in general develop better.

It is a natural product and can be biodegraded in nature. With this aspect, it is environmentalist and protects nature. In short, cocopeat is part of nature.

Uses: It can be used in professional agriculture, greenhouses or houseplants.

HOOKAH CHARCOAL – SHISHA COAL

PARAFFIN

CHEMISTRY

Polyvinyl Chloride

PVC (Polyvinyl chloride) is a plastic polymer with a wide area of usage. It is the third most produced synthetic plastic polymer in the world after polyethylene and polypropylene. It has two forms as solid and flexible. PVC (Poly Vinyl Chloride), which can be used in all areas of daily life, is an important member of the polymer family and is a modern synthetic (artificial) material. It is produced from two natural resources, Oil (43%) and Salt (57%). This material is durable and lightweight, fire resistant, has excellent insulating properties and low permeability.

Areas of usage; it is used in plastic pipes and fittings, window profiles, cable channels, food packaging and facade cladding products used in the infrastructure and construction industry.

S-PVC (Suspension Polyvinyl Chloride),

E-PVC (Emulsion Polyvinyl Chloride),

Polyethylene

Polyethylene (PE) is a highly durable, chemical resistant plastic used in a wide range of products. Polyethylene is produced by using ethylene. Polyethylene plastic can be low-density and high-density, but can also be molded. Polyethylene is a hard, robust, durable material that absorbs very little water. Good resistance to outdoor conditions and moisture, flexibility, superior chemical resistance can be counted as its general characteristics. It has a very wide usage area such as in plastic boxes, kitchenware, coatings, pipes and tubes, insulating layers in cables, packaging, and is cost-efficient.

Low Density Polyethylene (LDPE)

Linear low-density polyethylene (LLDPE)

High Density Polyethylene (HDPE)

Polypropylene

Polypropylene (PP) is a thermoplastic polymer with a wide range of applications, from parts used in the automotive industry to textile and food packaging.

Polypropylene is molded or extruded into many plastic products where hardness, flexibility, lightness and heat resistance are required. It can also be fibrated for use in industrial and home textiles.

Polypropylene is the second most common plastic raw material in the world.

It is preferred due to its cost advantage, robustness and easy molding. In addition to these, resistance to chemical oils and solvents, high strength, low friction coefficient, moisture and heat resistance are other advantages. It is a hard and opaque material.

Areas of usage; Packaging and labeling, textiles, stationery equipment, plastic parts, laboratory equipment, speakers, automotive sectors.

Homopolymer

Random Copolymer

Clock Copolymer

Polypropylene

PVC (Poly Vinyl Chloride), which can be used in all areas of daily life, is an important member of the polymer family and is a modern synthetic (artificial) material. It is produced from two natural resources, Oil (43%) and Salt (57%). This material is durable and lightweight, fire resistant, has excellent insulating properties and low permeability.

PVC Suspension(S-PVC)

PVC Emulsion(E-PVC)

Polystyrene

The plastic foam format is used as a food and industrial packaging product due to its transparency, processability and fluid properties.

Plastic solid format; is a polymer with high impact strength, low viscosity, opaque color, good tensile and flexural strength.

It is used in electronic product packaging and other industrial areas due to its resistance to liquid contact and protective properties. Polystyrene is naturally transparent, but can be made to different colors by adding various colorants.

General Use Polystyrene (GPPS)

High Impact Polystyrene (HIPS)

Extended Polystyrene (EPS)

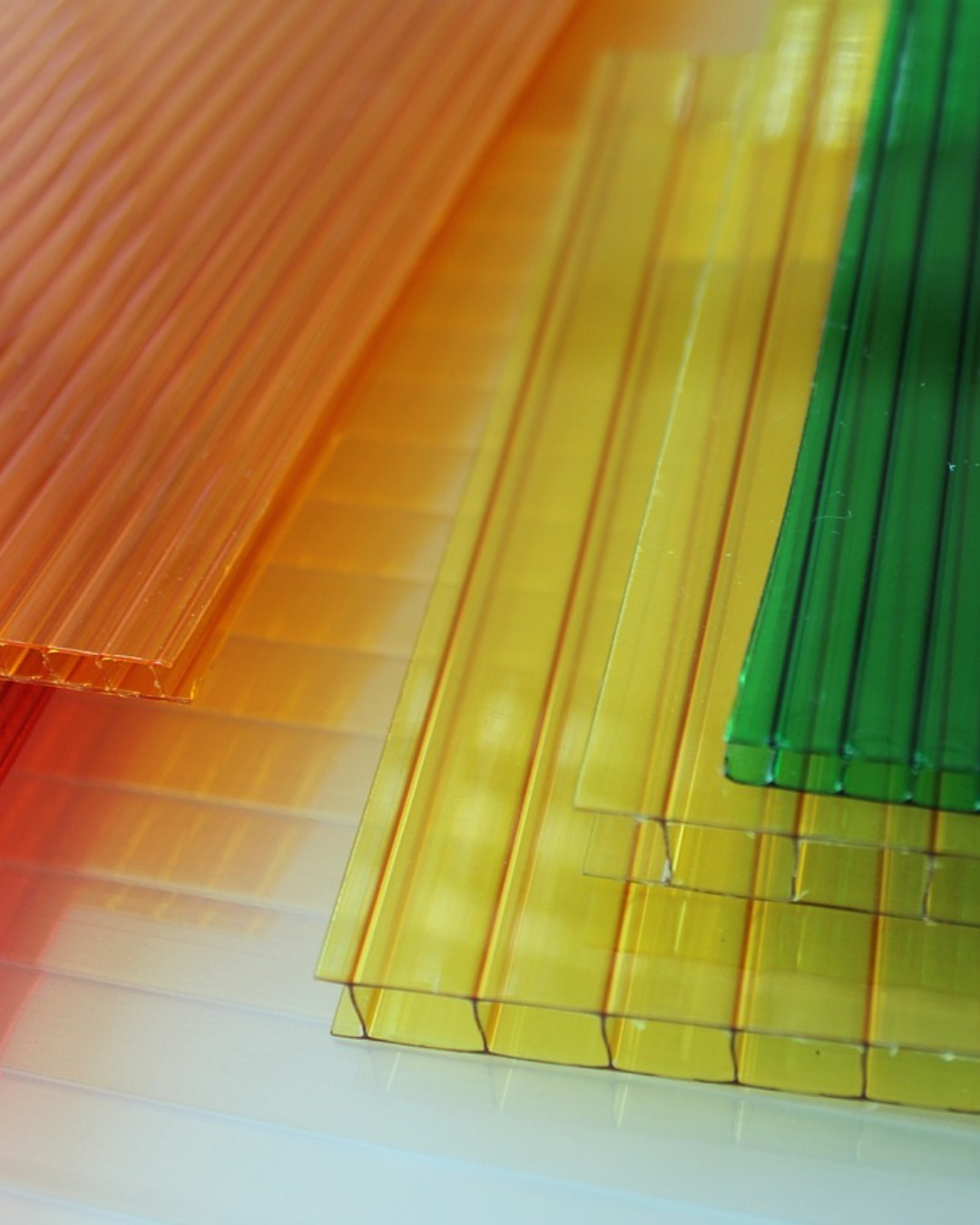

Polycarbonate

PC Extrusion

PC Injection

Acrylonitrile Butadiene Styrene (ABS)

Extrusion ABS

Injection ABS